80-82 Cao Duc Lan, District 2, HCMC, Vietnam

+84 76 865 6688

info@beetech.com.vn

+84 76 865 6688

About us

Contact us

80-82 Cao Duc Lan, District 2, HCMC, Vietnam

+84 76 865 6688

info@beetech.com.vn

+84 76 865 6688

About us

Contact us

Applications of RFID Tags

With this article, we aim to provide the most comprehensive guide on RFID tags in an online article, presented in a concise and clear manner. Our goal is for anyone seeking complete information about RFID to find it compiled here in a single web article.

We believe this will be useful for all users interested in RFID technology, and to ensure this information is up-to-date and verified, we encourage users to feel free to contact us at:

📧 Email: info@beetech.com.vn

🌐 Website: https://beetech.com.vn

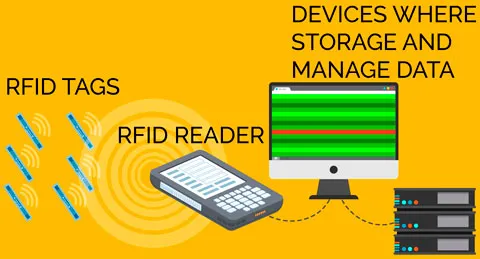

The acronym RFID stands for Radio Frequency Identification, and it refers to a system that collects, stores, and updates data through radio waves. The primary purpose of the RFID system is to uniquely identify objects, animals, and people by providing them with a unique identifier embedded in the RFID tag.

Although RFID technology has existed since the 1920s, it has only gained widespread adoption in industry and commerce globally over the past two decades. You may find it interesting to learn about the history of RFID, which we have previously explained here.

An RFID system is a combination of several elements that store, retrieve, and update information through interaction. These elements include:

These elements can be categorized under hardware, but the RFID system also relies on specific software, protocols, and communication standards, all designed to manage data effectively worldwide. We have previously written about RFID standards and protocols, which may also be of interest to you.

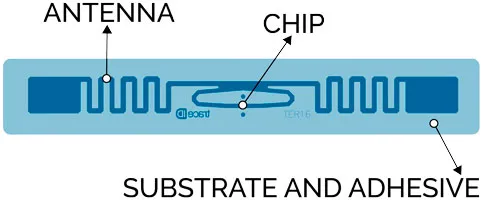

An RFID tag consists of:

The frequency of RFID refers to the size of the radio waves used for communication between the components of the RFID system. The lower the frequency, the fewer cycles a complete waveform can perform in one second. 1Hz equals one wave per second, 1KHz equals one thousand waves per second, and 1MHz equals one million waves per second.

The frequency type determines several behaviors of the entire RFID system. For example, lower frequencies result in slower data reading speeds but better reading capabilities near metals or liquids. Conversely, higher frequencies provide faster data reading speeds and longer reading ranges but are more sensitive to interference from metals or liquids in the environment.

To produce RFID tags, the company first designs the antenna based on the goals or needs to be addressed. Antenna designs can be created using various software tools.

We continually stay ahead of global technology trends, designing and manufacturing according to ODM (Original Designed Manufacturer) requirements through the latest specialized software. After designing the antennas, we proceed with their production.

The antennas we commercialize are made from aluminum or copper, in metallic colors, and some are even being developed using carbon fiber, depending on your choice.

Aluminum antennas are produced from very thin aluminum strips on PET. A reserved area marks the antenna region applied on the aluminum to remove excess material, leaving only the aluminum antenna shapes on the PET strip. Once the antenna strips are ready, they can move on to the next step in antenna production.

RFID chips store information transmitted through radio waves via the antenna and RFID reader. The chip is activated when it receives a radio frequency request from a reader, and in turn, it transmits the data it contains.

This activation can be either active or passive. RFID tags are passive when they do not carry a battery to provide the necessary power to transmit information. Therefore, the circuit is activated by induction, and the antenna occupies most of the space in the RFID tag, as it serves the dual function of receiving power and transmitting radio signals with the data stored in the chip.

The next step is to attach the chip to the antenna. This task is performed using bonding machines. There are various types of machines for producing RFID technology, and at Trace ID, we are supplied by the best manufacturers. In this case, the bonding and converting machines are from Mühlbauer.

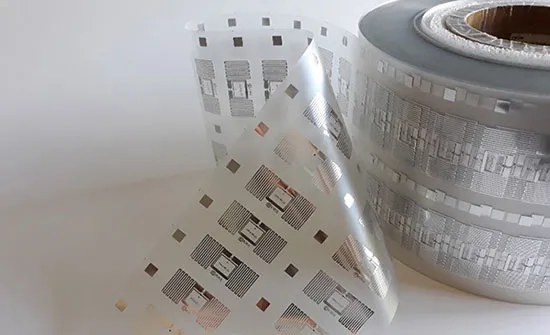

The antenna strip enters the bonding machine, and the chips are attached at precise points on each antenna strip using a type of plastic called epoxy. Once the strip is removed, it becomes a “dry inlay,” which is how we refer to antennas equipped with chips.

As mentioned, a dry inlay is an antenna equipped with a chip on a PET strip. It lacks adhesive and does not have the shape of a tag, so these dry inlays are not yet tags.

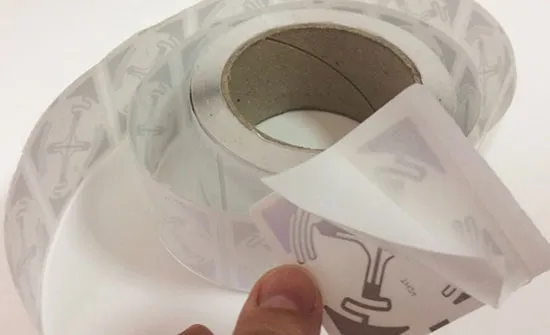

The converting machine transforms the dry inlay into a “wet inlay,” meaning that the strip not only carries dry inlays anymore but also provides inlays cut into tag shapes and includes adhesive.

When a customer’s order includes custom RFID labels rather than a wet inlay or white wet inlay, it is necessary first to produce the wet inlay. Producing the wet inlay is always essential for subsequently creating custom RFID labels. Additionally, the front faces can be made from various materials.

In this machine, the dry inlays covering the PET layer are coated with adhesive on a silicone-coated paper layer. They are then cut to the required tag dimensions. The cutting affects all layers except the silicone-coated paper. Finally, the excess material is removed, leaving only the wet inlays on the silicone-coated paper in the shape of a tag. Thus, the wet inlays can be removed from the silicone paper and affixed to any surface like a tag.

The production process for “white wet inlays” is similar to that for wet inlays, but an additional paper layer is added to the front of the tag.

As previously mentioned, the formats of custom RFID labels can vary widely depending on the specific needs of each RFID deployment. However, we can identify the most common formats in the RFID industry:

Regarding size, it can also vary widely, from small labels no larger than 10mm to larger labels of about 10cm or more. Similarly, the shape can differ greatly depending on the customer’s design.

Finally, we have individual labels attached to a roll of silicone-coated paper. In the images, you can see examples of dry inlays, wet inlays, white wet inlays, and labels.

The materials are quite diverse, ranging from paper to plastic; however, metal is generally avoided as it affects the proper functioning of radio frequencies. The only metals present are found in the chip and antenna.

After the RFID labels are produced, they proceed to the encoding line and, in some cases, to the printing step. At Trace ID, we encode the labels using SATO machines, which can also print pure elements or barcodes.

RFID tags undergo various quality control checks related to their performance, accurate encoding, etc. At Trace ID, we conduct quality control through measurement and testing solutions from the Voyantic brand.

RFID solutions are designed to trace the origin of everything, including people and animals. Each type of business or activity will require different RFID systems, but additionally, each customer may require a certain level of customization due to the characteristics of their environment and where they operate. Therefore, the most common applications are described below, but at Trace ID, we always consider and provide the appropriate level of customization for each customer’s specific needs.

RFID enhances the global logistics chain and increases efficiency by automating the identification and tracking processes. The largest retail companies and their suppliers now mark all their pallets, boxes, and items with RFID tags. Among the key benefits of working with a deployed global RFID system are better customer service, faster payments, higher shipment accuracy (with quicker and more reliable deliveries), and fewer damaged goods. All these benefits lead to optimized processes, simplified documentation, cost savings, and increased economic profits.

We have discussed the benefits of RFID technology in enhancing customer satisfaction and increasing sales. In summary, we can simply emphasize that thanks to RFID technology, we bolster security in tracking items to prevent theft and loss, as well as combat counterfeiting.

Additionally, the RFID system facilitates logistics between manufacturers, distribution centers, and stores, making it faster and more efficient. Of course, the efficiency of e-commerce is also enhanced with a suitable RFID application. Key retail sectors where RFID technology has become essential include:

Beetech has experience in all three sectors, particularly in RFID for jewelry, which we have worked extensively on.

The healthcare system requires applications and tools to manage, secure, and monitor assets and people within hospitals and among all integrated system centers globally, from primary healthcare centers to large state hospitals.

For all these reasons, RFID technology for healthcare is now an indispensable tool and will continue to evolve and deepen its integration.

RFID in hospitals is primarily useful for marking surgical instruments and disposable tools used in surgeries, which must be precisely controlled to avoid accidents or losses.

Additionally, it is used to control patient and staff access to different areas of the hospital, as well as to link each patient to their history through information stored in their RFID tags.

Companies, organizations, and agencies require systems for access control and traceability within their buildings. This is essential for security and collecting valuable information for managing people within the organization. Access control systems are also used in hotels for locking doors and saving energy.

Tracking and managing luggage at airports and in air transport is easier, safer, and more efficient thanks to RFID technology.

Tracking the times of participants in races and other sporting events is one of the most popular ways to utilize the capabilities of RFID technology.

Managing libraries and documents has traditionally been a very manual task for management units. However, when books and/or documents are provided with RFID tags that give them a unique identification number, tracking becomes more accurate and efficient. Additionally, the work becomes less tedious as the system can read the identification of multiple units at once, avoiding the need to manually identify each unit.

A primary concern in the food industry is the hygiene safety of products, making temperature control in the product cold chain essential. In upcoming articles, we will discuss Trace ID’s experience as a manufacturer of RFID labels for the food industry, including developing labels with batteries to monitor food temperatures.

If your interest focuses on any solutions in the food industry, please do not hesitate to contact us.

RFID technology faces many challenges ahead and numerous avenues for development. This is especially true in the realm of better customer service in retail, with the emergence of dual labels integrating UHF antennas with HF antennas, and in the healthcare sector and primary healthcare systems.

Source: https://www.trace-id.com/

What is NFC? What is RFID? What's the difference between NFC and RFID?

18/09/2025 02:55:49

RFID for Businesses: How to Implement an Effective Membership Card Program

17/09/2025 02:47:07

RFID Antennas – A Breakthrough Solution for Harsh Industrial Environments

08/09/2025 06:56:50

RFID: A modern management technology effectively replacing Barcodes

04/09/2025 03:21:00

Seamlessly Operating RFID Technology for Smart Manufacturing in Industry 4.0

19/08/2025 03:48:58

**RFID – A Breakthrough Solution for Modern Event Management in Vietnam**

28/07/2025 04:01:17