80-82 Cao Duc Lan, District 2, HCMC, Vietnam

+84 76 865 6688

info@beetech.com.vn

+84 76 865 6688

About us

Contact us

80-82 Cao Duc Lan, District 2, HCMC, Vietnam

+84 76 865 6688

info@beetech.com.vn

+84 76 865 6688

About us

Contact us

Benefits of RFID in Warehouse Management

RFID (Radio Frequency Identification) is an advanced Auto-ID technology that enables product tracking and identification through a unique serial number. Although RFID has been around for decades, it is only recently being fully leveraged thanks to advancements in supply chain systems and modern warehouse management technologies.

Warehouse operations such as inbound planning, storage, sorting, order picking, packing, cycle counting, and dispatching often rely heavily on manual labor, which leads to:

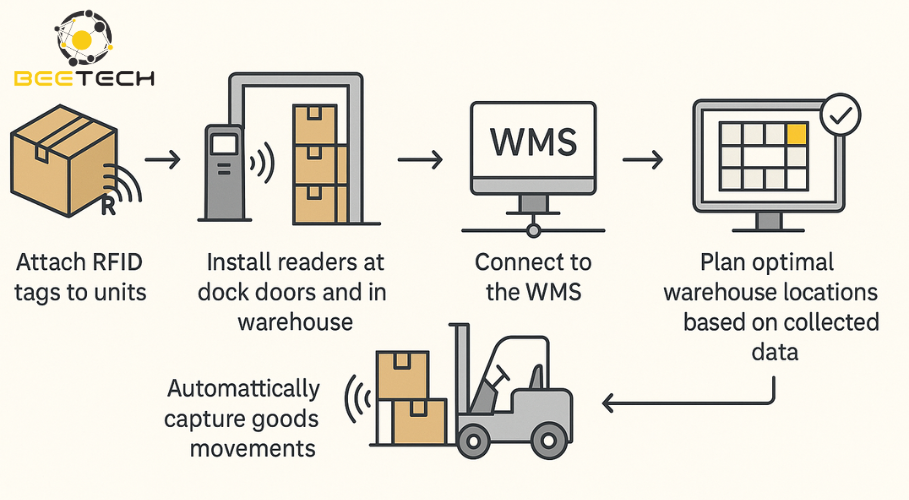

When integrated with Warehouse Management Systems (WMS), RFID offers outstanding benefits:

RFID can be integrated with GPS to track items during transit, helping reduce theft and loss throughout the supply chain.

The combination of RFID and WMS not only enhances inventory control but also accelerates process automation, reduces operational costs and errors, and improves overall competitiveness. RFID is the next essential step in building a smart and sustainable supply chain.

With over a decade of experience in automation and smart supply chain solutions, Beetech is proud to be one of Vietnam’s leading providers of end-to-end RFID systems—from hardware to integrated software platforms.

Beetech offers tailored services and products including:

High-performance RFID tags and readers designed for industrial and warehouse environments

Consultation, design, and deployment of RFID systems integrated with WMS based on your operational needs

Real-time inventory tracking software with intuitive interfaces and smart reporting tools

Comprehensive after-sales support and on-site technical assistance

👉 Contact Beetech today to discover the RFID solution that best fits your warehouse and logistics operations:

🌐 Website: www.beetech.com.vn

📧 Email: contact@beetech.com.vn

Beetech – Empowering your supply chain through smart RFID technology.

What is NFC? What is RFID? What's the difference between NFC and RFID?

18/09/2025 02:55:49

RFID for Businesses: How to Implement an Effective Membership Card Program

17/09/2025 02:47:07

RFID Antennas – A Breakthrough Solution for Harsh Industrial Environments

08/09/2025 06:56:50

RFID: A modern management technology effectively replacing Barcodes

04/09/2025 03:21:00

Seamlessly Operating RFID Technology for Smart Manufacturing in Industry 4.0

19/08/2025 03:48:58

**RFID – A Breakthrough Solution for Modern Event Management in Vietnam**

28/07/2025 04:01:17