80-82 Cao Duc Lan, District 2, HCMC, Vietnam

+84 76 865 6688

info@beetech.com.vn

+84 76 865 6688

About us

Contact us

80-82 Cao Duc Lan, District 2, HCMC, Vietnam

+84 76 865 6688

info@beetech.com.vn

+84 76 865 6688

About us

Contact us

Seamlessly Operating RFID Technology for Smart Manufacturing in Industry 4.0

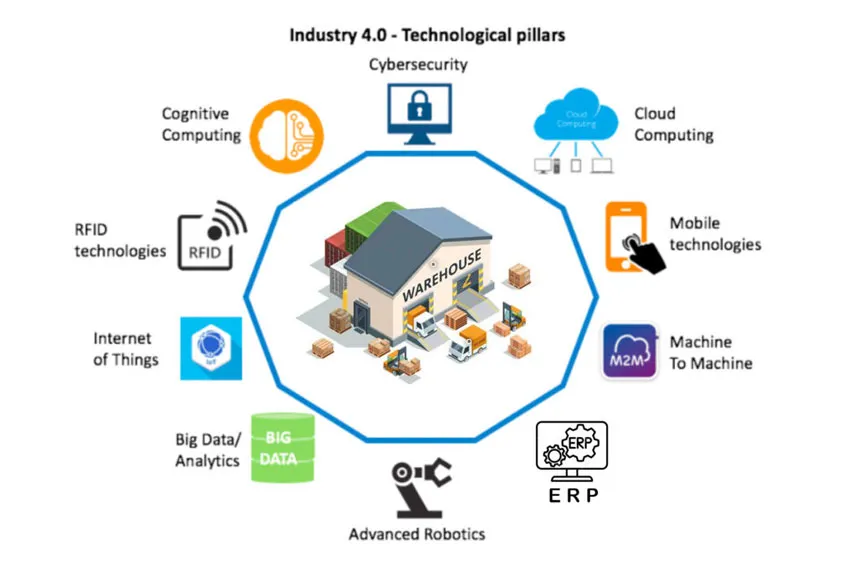

In the era of Industry 4.0, manufacturing businesses are no longer focused solely on productivity. They must also embrace automation, cost optimization, and the ability to flexibly respond to customer demands. To achieve this, one of the most essential technologies is RFID (Radio Frequency Identification) – a wireless identification solution that enhances efficiency in managing and operating the entire production chain.

With its ability to connect and share data in real time, RFID has become a core technology in building smart factories, where people, machines, and data work together in seamless harmony.

RFID empowers manufacturers to:

Track the entire production line: Every raw material or component is equipped with an RFID tag carrying a unique ID. Data is scanned and updated continuously.

Automate process control: RFID scanners on conveyors, machines, and robots provide precise instructions, reducing manual errors.

Simplify warehouse management and inventory control: All data is synchronized on the cloud, enabling real-time monitoring of stock levels.

As a result, businesses can reduce operating costs, shorten production time, and maximize management efficiency.

Today’s customers increasingly demand personalized products rather than mass-produced items. RFID provides the foundation for smart and flexible manufacturing by enabling companies to:

Integrate with MES and ERP systems for accurate order analysis.

Automate raw material purchasing, production scheduling, and distribution.

Adjust production lines dynamically to meet specific customer requirements.

Ensure faster, more accurate deliveries with higher reliability.

This allows businesses to shift from traditional mass production to flexible, customer-centric manufacturing, improving both customer satisfaction and loyalty.

In today’s highly competitive global market, applying RFID in smart manufacturing not only helps businesses cut costs and boost efficiency, but also provides a long-term competitive advantage.

RFID serves as a vital bridge, helping Vietnamese enterprises move closer to the smart factory model – where people, technology, and data are integrated into a unified digital ecosystem.

✅ If your business is looking for a cutting-edge solution to accelerate digital transformation in manufacturing, RFID is the ideal choice.

Let Beetech accompany your enterprise on the journey toward building smart manufacturing in the Industry 4.0 era.

What is NFC? What is RFID? What's the difference between NFC and RFID?

18/09/2025 02:55:49

RFID for Businesses: How to Implement an Effective Membership Card Program

17/09/2025 02:47:07

RFID Antennas – A Breakthrough Solution for Harsh Industrial Environments

08/09/2025 06:56:50

RFID: A modern management technology effectively replacing Barcodes

04/09/2025 03:21:00

Seamlessly Operating RFID Technology for Smart Manufacturing in Industry 4.0

19/08/2025 03:48:58

**RFID – A Breakthrough Solution for Modern Event Management in Vietnam**

28/07/2025 04:01:17