80-82 Cao Duc Lan, District 2, HCMC, Vietnam

+84 76 865 6688

info@beetech.com.vn

+84 76 865 6688

About us

Contact us

80-82 Cao Duc Lan, District 2, HCMC, Vietnam

+84 76 865 6688

info@beetech.com.vn

+84 76 865 6688

About us

Contact us

RFID Pick to Light Solution in Warehouse Management

In the past, warehouses were often viewed as supporting departments whose primary role was to store goods and release them when needed. However, in today’s modern business environment, warehouses are no longer simply places to “keep inventory.” They have become operational centers that directly impact revenue, costs, and customer experience.

Today, businesses face increasing pressure from multiple directions:

Rapid growth in daily order volumes

Omnichannel sales: physical stores, websites, e-commerce marketplaces

Demands for fast and 100% accurate delivery

Zero tolerance for errors from customers

Rising labor costs in warehouse operations

Difficulty in recruiting and retaining warehouse staff, with high turnover rates

In this context, any delay or error in warehouse operations can seriously disrupt the entire downstream chain, affecting sales performance, customer satisfaction, and brand reputation.

Among all warehouse activities, order picking is the process that:

Consumes 50–70% of total warehouse operating time

Requires the highest amount of labor

Is most prone to human error

In many warehouses today, workers still have to:

Read long picking lists

Search for item locations manually

Memorize SKUs, part numbers, and specifications

Rely heavily on personal experience

When warehouse operations are small, these issues may not be immediately apparent. However, as:

The number of SKUs increases

Daily order volumes grow

New employees frequently join and leave

👉 Picking errors increase exponentially.

Common consequences include:

Picking the wrong items

Picking insufficient or excess quantities

High return rates

Customer complaints

Loss of brand credibility

👉 Therefore, optimizing the picking process is the key to optimizing the entire warehouse operation.

If you have never heard of RFID or Pick to Light before, here is the simplest way to understand it:

RFID Pick to Light is a smart picking solution that uses light indicators to guide warehouse workers, ensuring they pick the right items, at the right location, in the right quantity.

Imagine a warehouse with:

Thousands of items

Hundreds of storage racks

Hundreds of orders per day

Instead of workers:

Carrying printed lists

Searching for locations

Relying on memory

With RFID Pick to Light:

LED lights illuminate at the exact storage locations

Displays show the required picking quantity

Workers simply follow the lights and pick the items

👉 No memorization. No searching. No guesswork.

RFID (Radio Frequency Identification) is a technology that enables systems to:

Identify items without direct scanning

Read multiple items simultaneously

Operate quickly, automatically, and accurately

Traditional Pick to Light systems only indicate where to pick, but risks still remain:

Workers may pick the wrong SKU if items look similar

Incorrect confirmation by pressing the wrong button

The system cannot be fully certain that the correct item was picked

👉 RFID acts as an intelligent verification layer, providing:

Automatic confirmation of correct items

Immediate detection of wrong SKUs

Real-time inventory updates

RFID Pick to Light = Visual guidance + Automated verification

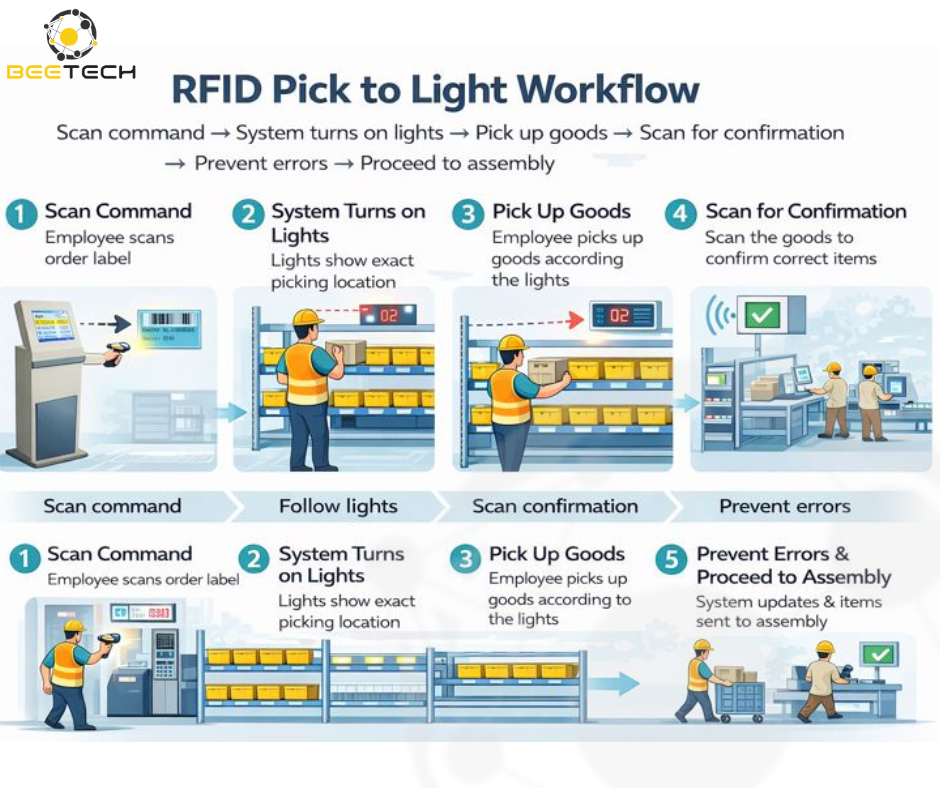

👉 This is a Pick to Light workflow with barcode/RFID control, designed to ensure correct component picking for a specific model, followed by transfer to the assembly stage.

🔹 The process begins when:

A production order is issued

Or a specific customer order/model is created

🔹 On the system (PC / MES / WMS):

The target model is selected

The system determines:

Required components

Quantity per component

Rack, bin, and storage locations

👉 This is known as “Picking for a specific model.”

🔹 The system generates an Order Label, which may include:

Model information

Engine / product code

Batch / lot number

Process step details

🔹 The operator:

Scans the barcode or RFID on the Order Label

Using a barcode scanner

👉 This scan activates the Pick to Light system.

🔹 After scanning:

The Control PC reads the order data

Performs mapping between required components and storage locations

🔹 The Control PC sends commands to:

The Controller

Which then distributes signals to the Junction Boxes

👉 This is the central logic and coordination step.

🔹 Controller

Receives commands from the Control PC

Coordinates the entire Pick to Light system

🔹 Junction Boxes (#1 → #N)

Each manages:

One rack group

Or multiple adjacent racks

They help:

Scale the system

Simplify wiring

Improve maintenance efficiency

👉 Junction Boxes function as zone-based control hubs.

🔹 When commands are issued:

Pick to Light indicators at required locations illuminate

Each indicator displays:

Required quantity

Or status (ON / OFF)

🔹 Workers simply:

Follow the lights

Go to the correct rack

Pick the displayed quantity

👉 No memorization. No searching. No manual list reading.

A key feature in the diagram is:

🔸 “Each Barcode Scanner as Indicator”

This means:

Each picking position or process step can use a barcode scanner as a confirmation mechanism

Or a combination of:

Pick to Light confirmation buttons

Component barcode scanning

🔹 After picking:

The worker either:

Presses the confirmation button

Or scans the component barcode

👉 The system confirms completion and turns off the light.

🔹 The “Indicators and parts of the barcode mapping” function plays a critical role.

The system compares:

Scanned component barcode

Against the valid component list for the selected model

👉 Results:

Correct component → accepted

Incorrect component → warning via light, sound, or screen

🎯 This implements a Poka-Yoke (error-proofing) mechanism, dramatically reducing picking errors.

🔹 When:

All Pick to Light indicators are turned off

All positions are confirmed

👉 The system confirms:

“Picking completed for this model”

🔹 Components are:

Grouped by model

Transferred to the Assembly area

👉 Ensuring:

Correct components

Correct quantities

Correct sequence

Rather than selling standalone hardware, Beetech delivers a complete, integrated solution, including:

Attached to bins, boxes, pallets, or products

Enable precise SKU identification

Installed directly on warehouse racks

Include:

LED indicators

Quantity displays

Confirmation buttons

Identify items without manual scanning

Detect incorrect picks immediately

Integrated with ERP, WMS, OMS

Coordinates orders

Provides real-time performance reporting

2–3× faster than traditional methods

Higher daily order throughput

Near elimination of picking errors

Reduced returns and complaints

New workers can operate immediately

No need to memorize warehouse layouts

Real-time stock visibility

Reduced loss and discrepancies

Lower labor costs

Reduced error-related costs

Typical ROI within 12–24 months

This solution is especially effective for:

E-commerce & fulfillment warehouses

Distribution & logistics centers

Manufacturing material warehouses

Large-scale retail warehouses

Warehouses with many SKUs and high order volumes

👉 The more complex the warehouse, the greater the benefits.

Beetech is not just a technology vendor, but a smart warehouse solution partner, offering:

Accurate assessment of real operational challenges

Scalable solution design

Certified RFID & Pick to Light hardware

Flexible software integration

Long-term operational support and expansion

RFID Pick to Light is not merely a technology upgrade, but a strategic step toward efficient, accurate, and sustainable warehouse operations.

With extensive implementation experience, Beetech delivers an RFID Pick to Light solution that is practical, easy to understand, and truly effective, enabling enterprises to prepare for long-term growth with confidence.

📧 Email: info@beetech.com.vn

🌐 Website: https://beetech.com.vn