80-82 Cao Duc Lan, District 2, HCMC, Vietnam

+84 76 865 6688

info@beetech.com.vn

+84 76 865 6688

About us

Contact us

80-82 Cao Duc Lan, District 2, HCMC, Vietnam

+84 76 865 6688

info@beetech.com.vn

+84 76 865 6688

About us

Contact us

Production Management Systems in Garment Industry

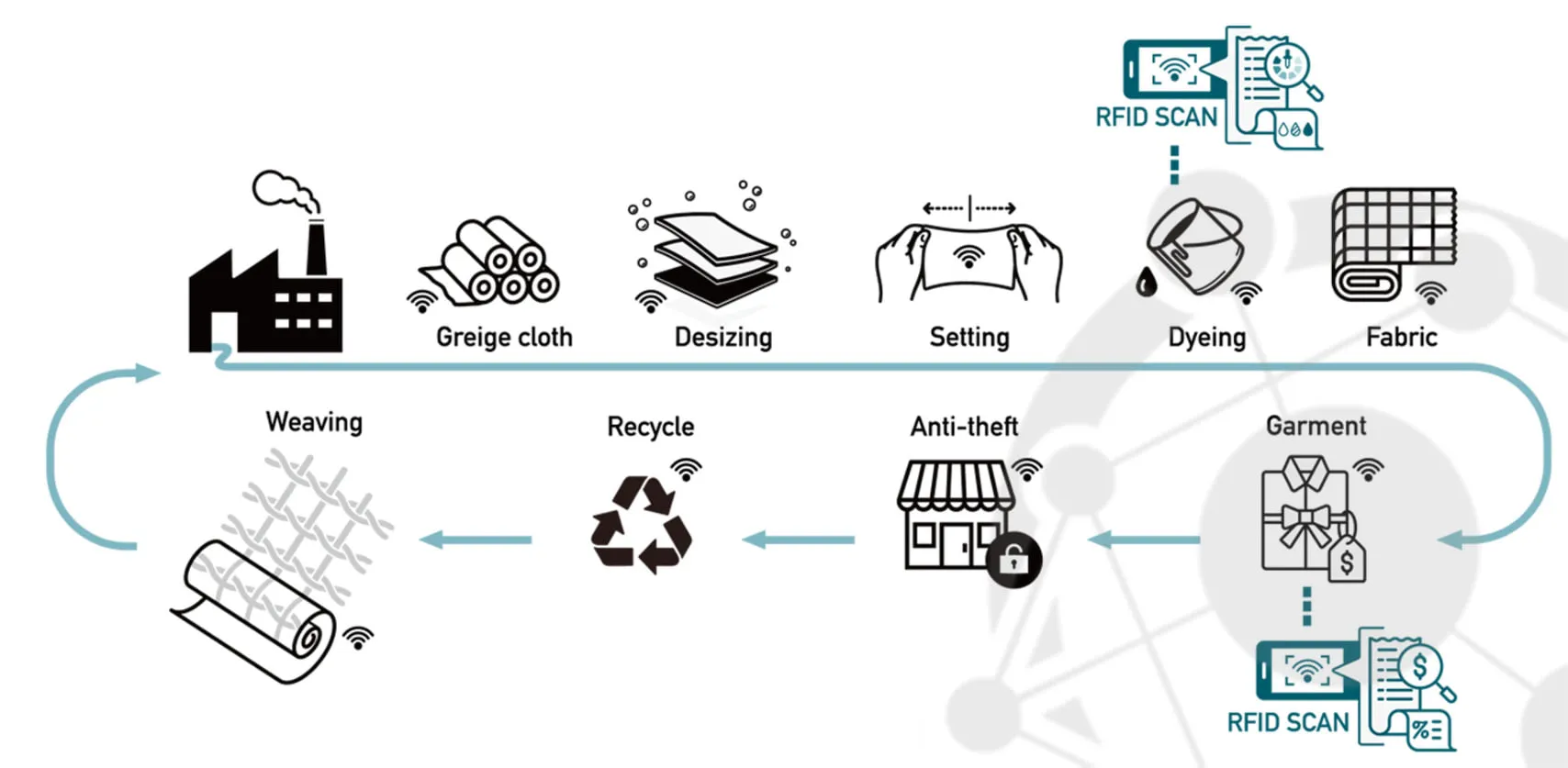

If sales are the most crucial task in a company’s business operations, then managing the production process in the apparel industry is just as important. Optimizing production management, especially in apparel manufacturing, has become a top priority. As a result, RFID technology is now an indispensable choice for many companies worldwide.

Recognizing the key areas for improvement in the apparel industry, Beetech focuses on smart solutions tailored for this sector. Managing the production process in apparel manufacturing involves a combination of solutions, including smart warehouse management and a production management system.

The production management solution for the apparel industry integrates RFID technology, providing a comprehensive view of an efficient, intelligent production process. Financial experts estimate that RFID technology can help apparel companies save billions of dollars. Additionally, this technology delivers fast and accurate data on items and their locations at any given time.

Brief Description of the Production Process Management Solution in the Garment Industry:

The movement through different stages also tracks workers’ KPIs throughout the production process. Each team’s output is displayed on a real-time dashboard to encourage productivity and competition among teams.

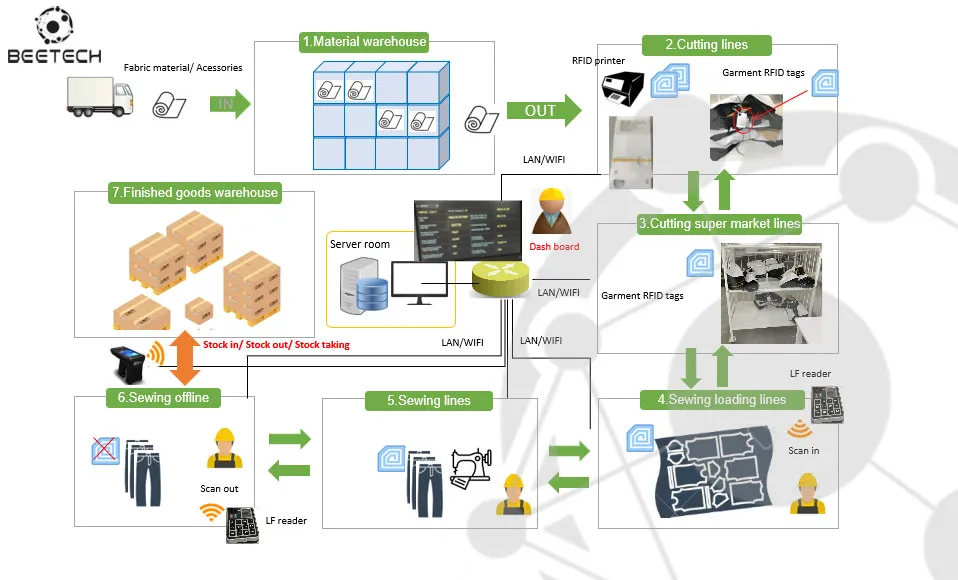

Overall Connectivity Model of the System and Business Process Flowcharts for RFID-Integrated Production

Overall System Connectivity Diagram

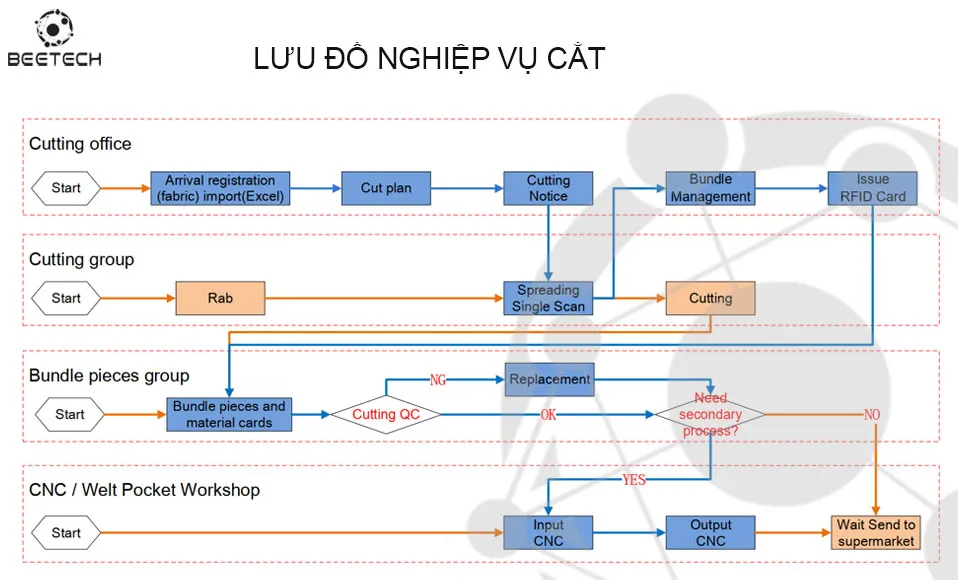

Cutting Process Flowchart

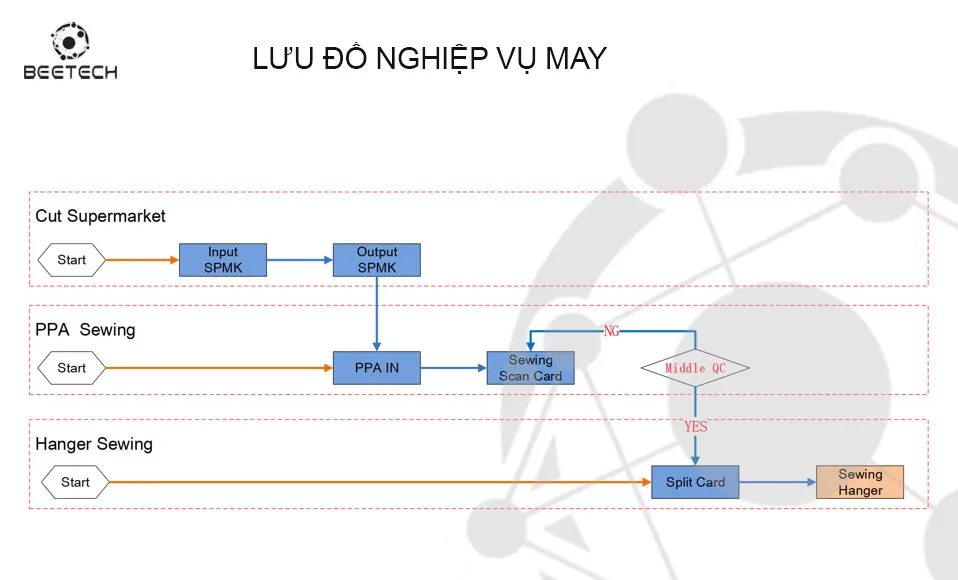

Sewing Process Flowchart

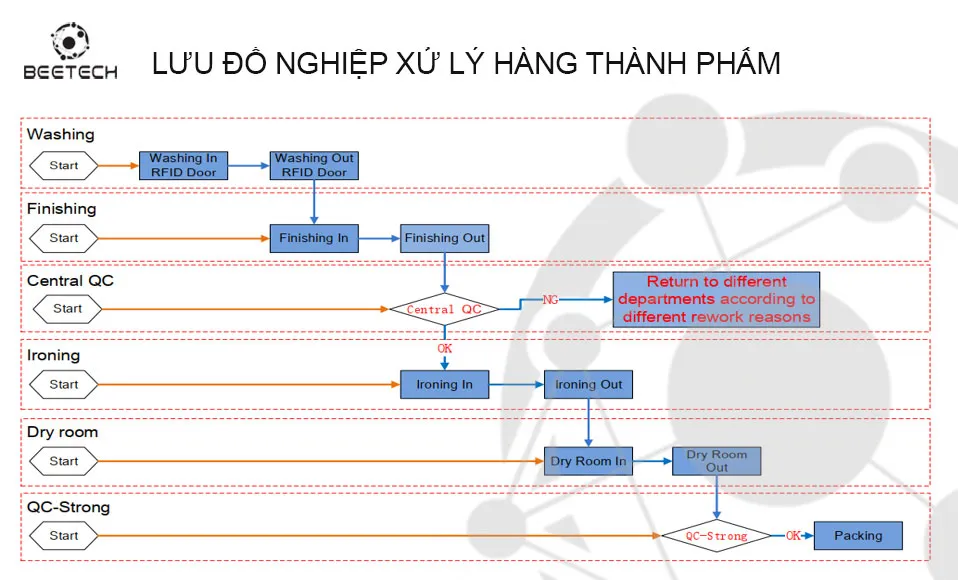

Finished Goods Processing Flowchart

Related Equipment:

Solution Benefits:

Some Real-Life Images

Contact Beetech:

With 12 years of experience in AutoID (barcode, RFID, etc.), Beetech is proud to be a leading consulting and design provider in Vietnam, offering smart devices and solutions. Our highly qualified engineers become an extension of your team, gaining deep insights into your application before developing and implementing a precisely tailored solution.

Contact us today to learn more about how we can help enhance efficiency and optimize workflows for your company. We are ready to support you!