80-82 Cao Duc Lan, District 2, HCMC, Vietnam

+84 76 865 6688

info@beetech.com.vn

+84 76 865 6688

About us

Contact us

80-82 Cao Duc Lan, District 2, HCMC, Vietnam

+84 76 865 6688

info@beetech.com.vn

+84 76 865 6688

About us

Contact us

The Ministry of Industry and Trade proposes new regulations on food traceability – A modern step forward for Vietnam’s food industry

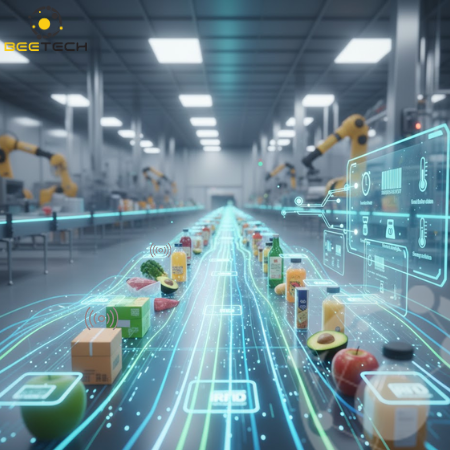

In the context of a global push for digital transformation and higher food safety standards, Vietnam’s Ministry of Industry and Trade has recently issued a Draft Circular regulating food traceability under the Ministry’s management.

This is an important step, not only to complete the legal framework for managing product quality, but also to help Vietnamese businesses proactively adapt to increasingly strict international market requirements.

On October 24, 2025, in Ho Chi Minh City, the Department of Industry (under the Ministry of Industry and Trade) organized a workshop to collect feedback on the Draft Circular. Deputy Minister Truong Thanh Hoai chaired the workshop, emphasizing: “Food safety is a crucial issue, directly affecting public health and the reputation of Vietnamese products. Establishing a centralized traceability system will lay the foundation for shifting from a reactive management model to a proactive one, based on digital and transparent data.”

According to Tran Viet Hoa, Director of the Department of Industry, the new Circular aims to establish a unified, mandatory, and modern legal framework for food traceability through a centralized electronic system. Implementing such a system will comprehensively transform management methods from manual paper-based processes to digital management, allowing real-time monitoring, analysis, and risk prevention.

Deputy Minister Truong Thanh Hoai likened the electronic traceability system to a “passport” that helps Vietnamese products access premium markets such as the EU, the US, and Japan regions with stringent origin certification and quality control requirements.

Beyond being a management tool, traceability also provides significant benefits for consumers, enabling them to easily verify product information, from the source of raw materials and production processes to transportation and distribution.

Recognizing that this transformation may put pressure on businesses, particularly small enterprises, the Ministry of Industry and Trade has developed a reasonable phased implementation plan from July 2026 to January 2027.

In the initial phase, large enterprises and high-risk product groups will adopt the system first, while smaller businesses will receive technical support and training to gradually adapt.

Feedback at the workshop indicated general support from businesses but also concerns about technology investment costs, especially since the Circular encourages the use of modern data carriers such as dynamic QR codes, RFID, or NFC for product identification.

Some participants suggested allowing a shared QR code for each production batch instead of individual products, reducing labeling costs while still ensuring traceability when necessary.

Among the technologies mentioned, RFID (Radio Frequency Identification) is considered a revolutionary solution for modern traceability. RFID is a wireless identification technology that allows data to be stored and transmitted through tags and readers without direct contact, unlike barcodes or QR codes.

Each RFID tag contains a microchip and a small antenna. When it passes through a reader’s coverage area, the information in the tag is automatically transmitted to the data management system. This technology enables fast, accurate, and human-error-free inventory, tracking, and traceability.

RFID’s key advantage is the ability to read hundreds of tags within seconds and operate reliably even in harsh environments such as cold storage, metal warehouses, or production lines.

In the food industry, RFID not only helps identify and manage individual products but can also integrate data such as temperature, humidity, and storage time crucial factors in determining food quality.

Globally, many countries have adopted RFID in food traceability systems to ensure safety and optimize operations.

In Japan, this technology is used in the seafood supply chain to monitor fishing, transportation, and storage.

In Europe, RFID has become mandatory in the dairy and meat sectors to ensure transparent information and rapid traceability in case of incidents.

In Vietnam, some pioneering enterprises in food processing, logistics, and smart agriculture have begun testing RFID for end-to-end supply chain management. Integrating RFID with centralized data management systems (IoT or ERP) allows businesses to monitor each batch in real time, minimizing fraud and data discrepancies.

Once the Ministry’s Draft Circular comes into effect, RFID could become a core technology helping Vietnam meet international traceability standards – meeting the requirements of major export partners while boosting domestic consumer confidence.

While QR codes mainly provide static information (visible only when scanned), RFID delivers dynamic data that updates automatically. In warehouses or production lines, staff do not need to scan each product manually; RFID readers automatically capture information as goods pass through checkpoints.

Moreover, RFID tags can store more information, are harder to replicate, and can be embedded within packaging or objects, ensuring high security. With connectivity to the Internet of Things (IoT), RFID enables full digitalization of the supply chain – from farm to table – making food origin data transparent, accurate, and easily shareable among stakeholders.

At the workshop, Mr. Tran Anh Thuy, Chairman and CEO of Phu Le Wine Joint Stock Company, noted that requiring modern data carriers such as electronic chips or individualized QR codes for each product could be costly for small enterprises. He suggested allowing a shared QR code per batch or printing codes on packaging instead of using specialized materials.

Similarly, Mr. Nguyen Dai Ngoc from the Ho Chi Minh City Food Safety Department recommended implementing the system in phases, prioritizing high-risk product sectors first, and clarifying the responsibilities of producers and retailers in updating traceability data.

These opinions have been acknowledged by the Ministry to finalize the Circular, aiming for a model that ensures strict management while allowing businesses to implement flexibly according to their capabilities.

Building a unified electronic traceability system is not only a response to global trends but also an opportunity for Vietnam to enhance product competitiveness and reputation.

When consumers can verify origins clearly, trust in Vietnamese brands strengthens, paving the way for exports and sustainable development.

RFID, with its automation and high data security, is seen as a crucial component in achieving this goal. In the near future, as the electronic traceability system operates fully, Vietnam will gradually form a “food data economy” – where every product has a digital identity, every journey is recorded, and all consumers are protected by technology.

The Draft Circular on food traceability represents a significant step forward in Vietnam’s food industry digitalization. The adoption of RFID technology will help businesses manage more transparently, trace products faster, and boost consumer confidence. This is not only a regulatory requirement but also a key enabler for Vietnamese products to reach global markets.

With over 12 years of experience in the AutoID industry, Beetech takes pride in being one of Vietnam’s leading providers of RFID solutions and smart devices.

Our team of experienced engineers accompanies your business through every stage from consultation and implementation to full lifecycle support ensuring your RFID systems operate seamlessly and deliver maximum value.

Let Beetech be your trusted partner on the journey to building intelligent management systems that enhance your competitiveness and drive success in the digital era.

📧 Email: info@beetech.com.vn

🌐 Website: https://beetech.com.vn

See more products: Here

RFID in Logistics – The Core Technology Powering Modern Supply Chains

17/11/2025 06:21:25

RFID – The “Silent” Technology Transforming How Vietnamese Businesses Manage Their Inventory

13/11/2025 07:16:17

National Assembly Proposes Using Electronic Chips to Monitor Drug Addicts

12/11/2025 03:56:38

Vietnam’s RFID Logistics Market: Rapid Growth from 2025 to 2031

12/11/2025 03:13:47

RFID – When data becomes reality: The journey to building systems of reality in the digital ge

07/11/2025 02:57:55

Challenges in RFID Reading Performance and Environmental Conditions

06/11/2025 02:36:26