80-82 Cao Duc Lan, District 2, HCMC, Vietnam

+84 76 865 6688

info@beetech.com.vn

+84 76 865 6688

About us

Contact us

80-82 Cao Duc Lan, District 2, HCMC, Vietnam

+84 76 865 6688

info@beetech.com.vn

+84 76 865 6688

About us

Contact us

RFID – When data becomes reality: The journey to building systems of reality in the digital ge

As digital transformation accelerates across the globe, the need for accurate, transparent, and efficient management of assets, materials, and operational processes has become more critical than ever especially in sectors like defense and healthcare. Yet even massive organizations such as the U.S. Department of Defense (DoD) continue to face challenges in achieving a “clean” financial audit, largely due to limitations in accurately tracking and verifying their physical assets with reliable data.

According to the DoD’s 2024 financial audit, the department still had four major weaknesses in the “inventory” category, including a lack of sufficient evidence of assets within its internal systems of record. In other words, no matter how robust their recordkeeping systems are, they still lack the “reality layer” needed to ensure that data truly reflects what exists in the real world.

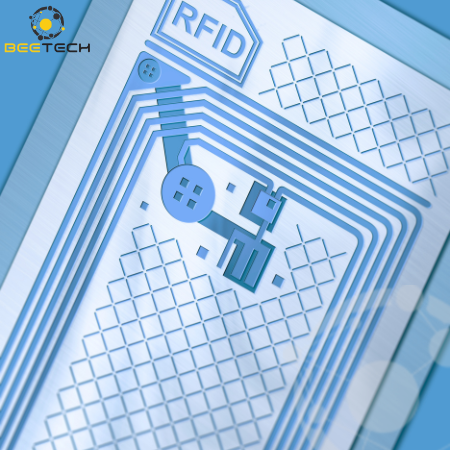

That’s where RFID (Radio Frequency Identification) technology comes in. Rather than relying solely on “systems of record” databases dependent on human data entry RFID introduces the concept of “systems of reality,” where data is collected objectively, automatically, and with near-perfect accuracy.

Discussing the role of RFID, Chad Tripp, RFID Engagement Manager for Federal and Healthcare Sectors at Zebra Technologies, explains:

“It’s not that RFID replaces systems of record it adds a layer of objective reality to your existing data. In the past, you had to trust that someone entered data correctly. But under stressful, fast-paced operations, mistakes happen. With RFID, information comes directly from the item itself, not from a person. That gives you a truly honest view of your processes.”

Put simply, instead of guessing what’s causing operational bottlenecks or discrepancies, RFID reveals the truth through real-world data. When departments disagree over an issue, leaders no longer need to assume that “the truth lies somewhere in the middle” because now, “the truth lies in the RFID data” collected directly from physical reality.

By eliminating human bias, delays, and inaccuracies, RFID allows organizations to gain a real-time, panoramic view of their operations, helping them streamline processes, reduce waste, and improve overall efficiency.

The power of RFID lies in how differently it works compared to traditional barcode systems. Barcodes require line-of-sight between the scanner and the label, but RFID does not.

Instead, RFID uses radio waves to identify and transmit data between a tag attached to an object and a reader. It’s similar to electronic toll collection systems on highways where an RFID tag on a vehicle communicates with a toll gate without requiring the driver to stop.

Tripp offers a vivid analogy:

“If barcodes are like fishing with a single rod catching one fish at a time then RFID is like casting a net and hauling in hundreds at once. A worker can scan hundreds of items simultaneously without even seeing them.”

In logistics environments, that difference is transformative. For example, during goods receiving, a single pallet might contain hundreds of mixed boxes. With barcodes, workers must break down the pallet, scan each box, and manually verify counts a slow, error-prone process. With RFID, the entire pallet can be scanned and verified within seconds as it passes through a dock door.

This level of automation and speed makes RFID a strategic game-changer for supply chain management, logistics, and large-scale asset tracking systems.

The advantages of RFID are already well known to the DoD and other federal agencies. It’s being deployed across a wide range of applications from passport management to maintenance and repair of military aircraft, ships, and vehicles, as well as healthcare and scientific research.

At the U.S. Department of Veterans Affairs (VA), RFID is becoming indispensable. VA hospitals use RFID to track medical equipment, surgical tools, and medical supplies, ensuring that everything is ready and maintained for use at any time. This capability is vital in healthcare, where a single misplaced or unmaintained device could have serious consequences.

RFID is also gaining traction in laboratories, helping scientists manage and locate critical instruments, samples, and chemicals.

“When a PhD walks into a lab, they need to instantly find every tool and material required to work,” Tripp emphasizes. “Any downtime is costly it slows progress on mission-critical projects.”

By minimizing downtime and ensuring near-perfect accuracy, RFID is rapidly becoming the new standard in asset and inventory management across research, healthcare, and defense sectors.

Despite its clear advantages, RFID adoption remains relatively modest, even in the commercial sector hovering around 10–15%. The main barrier? Cost, particularly the price of individual RFID tags.

However, in recent years, costs have dropped significantly, making the technology more accessible than ever.

“Twenty years ago, an RFID label cost about 30 cents. Today, large-volume buyers can get them for under five cents, and prices continue to fall,” says Tripp.

Retail giant Walmart once predicted that when RFID tags fell below five cents, mass adoption would follow — and that prediction is becoming reality.

While RFID tags still cost more than traditional barcodes, which are only fractions of a cent, organizations seeking to transcend outdated processes and achieve breakthrough performance see RFID as a worthwhile investment.

Beyond cost savings, RFID offers unprecedented visibility allowing managers to know exactly where every asset is, when it moves, and its current status, all in real time.

“Sure, the initial cost might give some customers pause,” Tripp admits. “But once they see the real-world impact from those who’ve implemented it successfully, they realize the value far outweighs the price. You simply can’t imagine what’s possible until you see RFID data in action.”

In an age where data is the world’s most valuable asset, RFID transforms data into living truth reflecting the precise movements of the physical world.

With its ability to identify items instantly, work without contact, and deliver real-time accuracy at decreasing costs, RFID is closing the gap between recorded information and operational reality.

For the military, RFID ensures every asset and component is accounted for. For hospitals, it guarantees readiness of life-saving equipment. And for businesses, RFID marks the dawn of a new era the era of “systems of reality,” where data isn’t just recorded but alive, accurate, and trustworthy.

With over 12 years of experience in the AutoID industry, Beetech is proud to be a leading provider of RFID solutions and smart devices in Vietnam.

Our team of skilled engineers supports businesses throughout the entire lifecycle from consultation and implementation to maintenance ensuring that every RFID solution operates efficiently and delivers maximum value.

Let Beetech be your trusted partner in building intelligent management systems that enhance competitiveness and drive your organization forward in the digital era.

📧 Email: info@beetech.com.vn

🌐 Website: https://beetech.com.vn

See more products: Here

RFID in Logistics – The Core Technology Powering Modern Supply Chains

17/11/2025 06:21:25

RFID – The “Silent” Technology Transforming How Vietnamese Businesses Manage Their Inventory

13/11/2025 07:16:17

National Assembly Proposes Using Electronic Chips to Monitor Drug Addicts

12/11/2025 03:56:38

Vietnam’s RFID Logistics Market: Rapid Growth from 2025 to 2031

12/11/2025 03:13:47

RFID – When data becomes reality: The journey to building systems of reality in the digital ge

07/11/2025 02:57:55

Challenges in RFID Reading Performance and Environmental Conditions

06/11/2025 02:36:26